| People | Research |

|

Modeling design and experimentation of diffusion-based chemical concentration generation

We have extended our electrokinetic microfluidics modeling approach to develop models of

chemical concentration gradient generators (CGG), which are pressure-driven microfluidic devices generating desired

chemical concentration gradients for applications in cell biology, biochemistry, surface patterning and microfabrication.

The CGG models are again based on analytical constituent element models linked in a system-level representation.

Based on the models, we have conducted the synthetic design and experimental validation of novel

CGG devices that exploit partial diffusive mixing in multi-stream laminar flow. The devices construct complex profiles of

chemical concentrations by laterally combining the constituent profiles (e.g., linear and bell-shaped) generated in simple

Y- or "Psi"-shaped mixers. An iterative simulation approach that incorporates our system-level models of CGG networks is developed

to identify the sought-after combinations of geometrical and operating parameters (e.g., inlet flow rates and inlet sample

concentrations) for the device design. Microfluidic CGG chips are fabricated and experimentally characterized using optimal

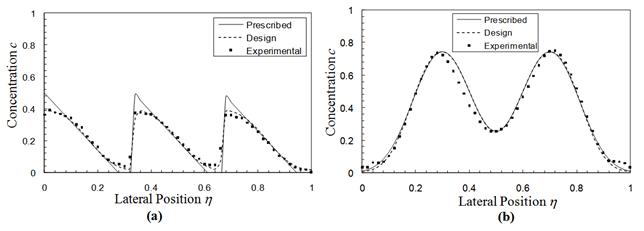

layout and operating conditions selected by the design process. The concentration profiles obtained from the experiments agree

well with the design specification (prescribed ones). These gradient generators allow much simplified topological designs and

afford improved reliability when compared with most other CGG devices that are based on complete mixing of chemical species.

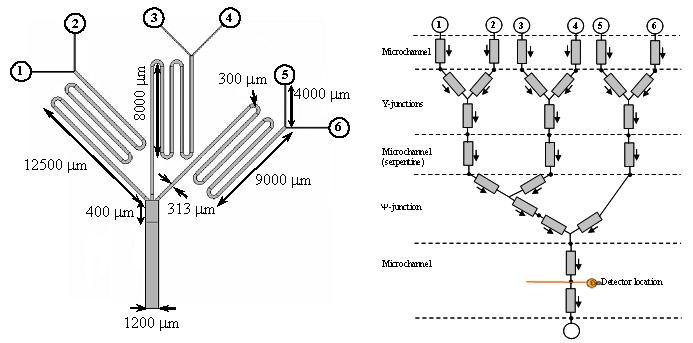

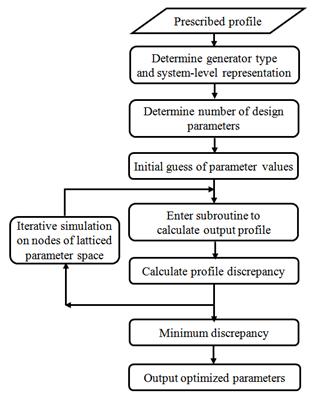

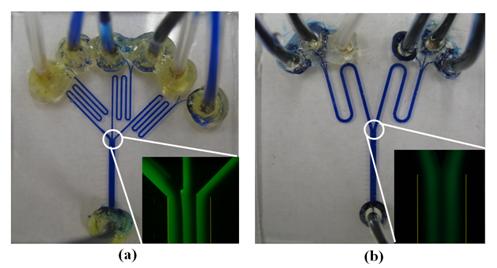

Modeling and design of microfluidic chemical concentration generation (CCG) devices. (a) A sawtooth-shaped CGG device and (b) its representation for system-level model. The microfluidic network of a sawtooth-shaped CGG device is decomposed into a network of microchannels, Y-junctions and "Psi"-junctions.  A flow chart illustrating the iterative simulation-based design approach.  The CGG device fabricated by soft lithography techniques. (a) CGG for sawtooth-shaped profile, and (b) CGG for double bell-shaped profile. The insets show the generation of concentration gradient using fluorescent solution.  Comparison of the prescribed, design, and experimental results: (a) the sawtooth-shaped concentration profile, and (b) double bell-shaped concentration profile. Results show agreement of prescribed, design and experimental profiles within 10% error.

|